Important member of CST02 family

Servo motor controlled crimping presses

Apply to both insulated and non-insulated terminals

Twist conductor before crimping

Processing reeled terminals

JCW-CST02 INSU-R

Important member of CST02 family

Servo motor controlled crimping presses

Apply to both insulated and non-insulated terminals

Twist conductor before crimping

Processing reeled terminals

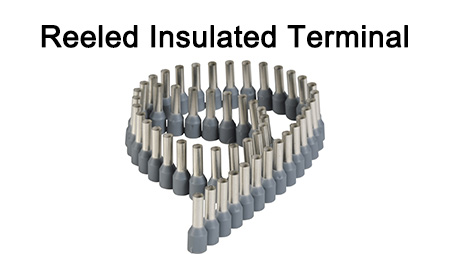

Pre-insulated Terminal In Reel

Wire Mark & Tape-on Terminal Crimp

| Model | JCW-CST02 INSU-R Fully Automated Wire Cutting Insulated Terminal Crimping Machine |

| Function | Wire cutting, Single / Dual-end strip and twist, Single / Dual-end crimp, Cut depth, Pull-off length, Insulated terminal, non-insulated terminal, etc |

| Wire cross-section | 0.3 - 4 mm² ( AWG 22 -11 ) [ can be custom ] |

| Strip length | 1.5 - 12 mm |

| Cut length ( L ) | 45 - 99999 mm |

| Cut length tolerance | ± 1mm + 0.002 x L |

| Crimp force | 20KN (2.0 tons) [ 40 KN on request ] [ Servo model ] |

| Detector | Wire lack, Terminal crimping, Wire knot, Air pressure [ CFM on request ] |

| Production rate | 900 - 10000 pcs/h by 100 mm wire length, insulated terminal |

| Display | 7" touch screen, English / Chinese [ other languages on request ] |

| Power supply | AC 110 - 220V ± 10%, 50 / 60 Hz |

| Air supply | 0.4 - 0.6 MPa [ Clean and dry air ] |

| Weight | 388KG |

| Dimensions | L 1000 x W 800 x H 1500mm Straightener: 800 mm |

| CE-Conformity | Complies with CE equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |