Single-end crimp to solder

Wire Range: AWG 32 - 16

Cutting length: 8 - 850 mm [ 1200/1500/1800mm on request ]

Stripping length: 0.1 - 11.5 mm

Tinning length: 0.5 - 10.5 mm

Crimping force: 2 tons

6600 pcs/h by 100mm wire length

JCW-CST06

Single-end crimp to solder

Wire Range: AWG 32 - 16

Cutting length: 8 - 850 mm [ 1200/1500/1800mm on request ]

Stripping length: 0.1 - 11.5 mm

Tinning length: 0.5 - 10.5 mm

Crimping force: 2 tons

6600 pcs/h by 100mm wire length

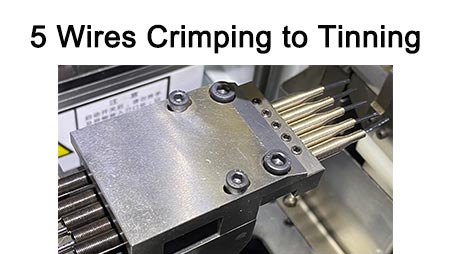

Fully-auto 5-Wires Crimping & Tin Dipping Machine

JCW-CST06 Fully Automatic Wire Stripping Crimping and Tinning Machine

High output, 5 wires, fully servo motorized

Feature of the machine

The JCW-CST06 is a highly efficient automatic 5 wires crimping and soldering machine, serves various applications: wire cutting and stripping, terminal crimping, wire twisting, fluxing and tinning. Compared with single wire machines, the JCW-CST06's processing capacity is expanded to 6600 pieces per hour. The standard model offers 850mm cutting length, 1200mm-1500mm-1800mm are all optional. Tinning can be turned off if needs only wire stripping and terminal crimping.

The JCW-CST06 is designed for meeting high output requirements on terminal crimping and wire tinning. Crimp applicator changeover is simple and fast, both vertical and horizontal types are suitable. The smoke collect device ensures a clean and safe working environment.

High-quality processing and simple operations

The JCW-CST06 integrates high-quality components: 5 sets of MITSUBISHI servo motors, THK/TBI guide, FESTO valve, highly rigid transmission structure, high-speed control system. A super user-friendly interface and 7" touch screen interface offer accurate input and clear vision. A motorized digital wire twisting monitor brings perfect wire tinning. Vivid detectors ensure high-quality production: wire lack detection, wire knot detection, stripping detection, crimping detection, air pressure detection, etc.

Various peripherals and options

- Crimping force monitoring ( CFM )

- Short mode allows 8mm length with crimping and tinning

- 1200mm / 1500mm / 1800mm cutting length

- Wire prefeeder for keeping proper wire tension

- Conveyor belt for stacking finished wire

- Customize HMI, language & logo

| Model | JCW-CST06 Automatic 5 Wires Crimping to Tinning Machine |

| Function | Single/dual end stripping, Full stripping, Partial stripping, Middle stripping, Front side crimping, Rear side fluxing & tinning, Cut depth, Pull-off length. |

| Wire range | AWG 32 - AWG 16 |

| Raw material | PVC, Teflon, Low halogen, etc. |

| Crimp force | 2 tons [ 20 KN ] |

| Cut length ( L ) | 8 - 850 mm [ 1200-1500-1800mm on request ] |

| Cut length tolerance | 0.002 x L |

| Strip length | 0.1 - 11.5 mm |

| Twist length | 0.5 - 10.5 mm |

| Tinning length | 0.5 - 10.5 mm |

| Production rate | 6600 pcs/h by 100mm cutting length |

| Data library | 100 programs |

| Detector | Wire lack, Wire knot, Wire stripping, Terminal crimping, Air pressure |

| Smoke collect system | Yes |

| Optional peripherals | CFM, Wire unwinder, Marking system |

| Display | 7" touch screen, English / Chinese [ other languages on request ] |

| Power supply | AC 110 - 220V ± 10%, 50 / 60 Hz |

| Rated power | 2500 W |

| Air supply | 0.5 - 0.8 MPa [ Clean and dry air ] |

| Weight | 500KG |

| Dimensions | L 1720 x W 750 x H 1500mm |

| CE-Conformity | Complies with CE equipment guidelines relative to mechanical and electrical safety and electromagnetic compatibility. |