Compatible with side-feed & end-feed terminals

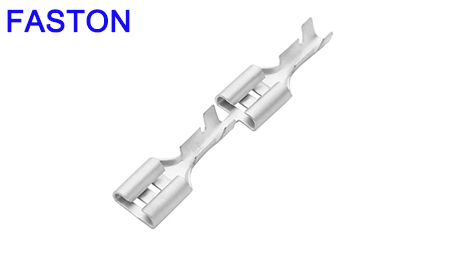

Shark teeth / 187 / 250 / O ring / Flat terminals

3 tons crimping force [ 4 tons optional ]

Wire range AWG 32 - 14 [ 2mm² ]

PVC, Teflon, Silicone, Low-halogen, Fiberglass cables

Safety cover & EM-STOP button are optional

![Automatic Battery Cable Cutting Machine [ 8 Rollers ]](/data/thumb/res/en/20250509/jcwelec-cs05-cable-cut-strip-machine_1137102b.jpg_20250509172909_800x800.jpeg)